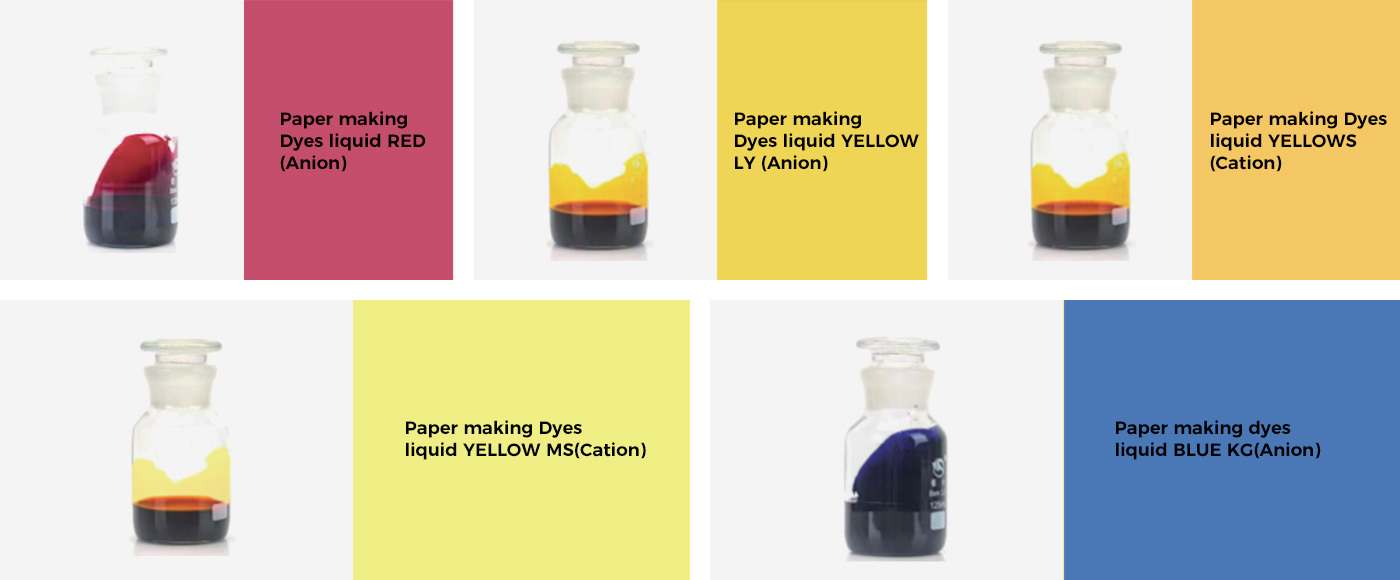

Paper Making Dyestuff

Category:

Product Introduction

Technical Indicators

| Name | Dyestuff Liquid RED (Anion) | Dyestuff Liquid YELLOW LY (Anion) | Dyestuff Liquid YELLOW MS (Cation) | Dyestuff Liquid YELLOW S(Cation) | Dyestuff Liquid BLUE KG(Anion) |

| Appearance | dark orange liquid | Brown red liquid | Brown red liquid | Brown red liquid | black liquid |

| Dissociation | Anion | Anion | Cation | Cation | Anion |

| Firmness | High fastness compared with similar dyes. | High fastness compared with similar dyes. | High fastness compared with similar dyes. | High fastness compared with similar dyes. | High fastness compared with similar dyes. |

| Strength | 100±3(Compare to standard item) | 100±3(Compare to standard item) | 100±3(Compare to standard item) | 100±3(Compare to standard item) | 100±3(Compare to standard item) |

| Viscosity | ≤50mPa.s (20℃) | ≤50mPa.s (20℃) | ≤30mPa.s (20℃) | ≤50mPa.s (20℃) | ≤30mPa.s (20℃) |

| Density | ~1.1g/cm³ | ~1.2g/cm³ | ~1.1g/cm³ | 1.05-1.15g/cm³ | ~1.1g/cm³ |

| PH value | 7.2-9.0 | 7.0-8.0 | 3.5-5.5 | 3.5-5.5 | 8.0-10.0 |

| Stability | This product has high storage stability, but long time under the freezing point, may solidify, put to room temperature or heating can be restored to the original state, and has no adverse effect on the use effect. |

||||

Aplication feature

This product is mainly used for dyeing kraft or test liner or board paper It has high affinity for mechanical pulp, recycled pulpnon-bleached chemical pulp and other fibers containing more lignin,and can get good dyeing effect.Com- pared with similar products, it has higher fastness to sunlight.

key word:

Equipment

Warping Workshop

All our products are made of imported filament and raw materials, such as the Perlon® Filament. We also use world's most advanced German Schlatter Jagar warping machine. We control product processes and materials from the original procudure, so as to achieve the best product quality.

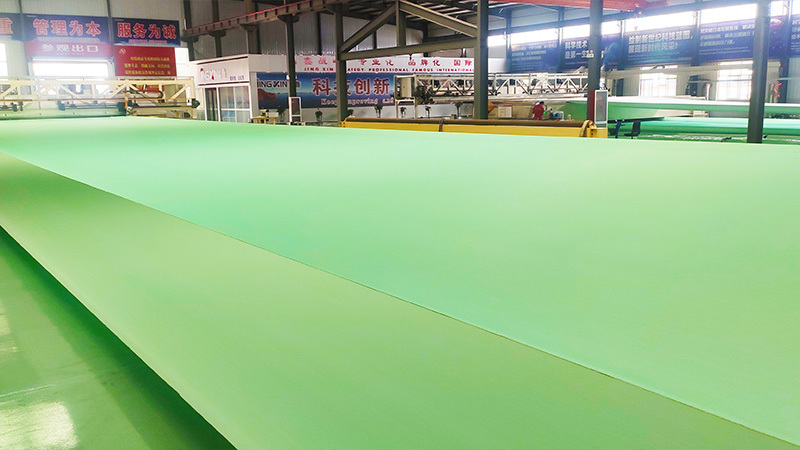

Weaving Workshop

The task of weaving is to interweave the warp and weft processed by the warping process into fabric through the loom according to the fabric specification requirements and certain process design. The warp and weft strength, wear fastness and air permeability of fabrics directly affect the service life of forming fabric and various indexes in production and use processes. We have the most advanced and widest 16 meter Jurgens loom in the world, and the weaving speed, strength and stability have reached the world-class level.

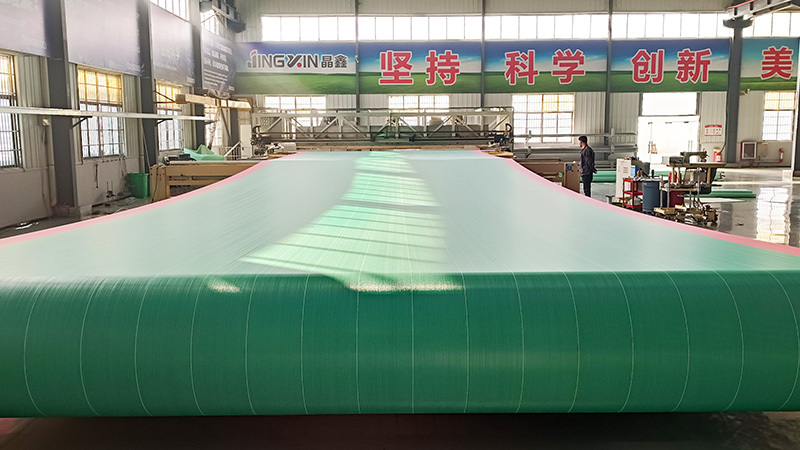

Seaming workshop

The Seaming process is the key process of forming fabrics. In this process, the forming fabrics been size cutting and pre hot setting, then make both ends seamed according to the same fabric design and constructions in the production process. The process requires high technical level, complex process and a long time spending. The firmness and flatness of the seaming will directly affect the requirements in the using process. We have the world's most advanced Austrian WIS automatic seaming machine. The firmness, flatness and stability of the seaming have reached the world-class level.

Seaming Workshop

The Seaming process is the key process of forming fabrics. In this process, the forming fabrics been size cutting and pre hot setting, then make both ends seamed according to the same fabric design and constructions in the production process. The process requires high technical level, complex process and a long time spending. The firmness and flatness of the seaming will directly affect the requirements in the using process. We have the world's most advanced Austrian WIS automatic seaming machine. The firmness, flatness and stability of the seaming have reached the world-class level.

Packaging Workshop

Packaging is an important process. The firmness of the packing box is directly related to the transportation safety and products integrity. We use thickened high-density fumigation-free plywood, supplemented by solid square wood as reinforcing beam. Three thick steel pipes are used for forming fabric packaging, covered with bubble film and wrapped firmly with adhesive tape to ensure that it will not roll and slide during transportation. The bearing capacity of the box is up to 1 ton, which can meet the requirements of ocean transportation.

Honor

Qualification certificate

Related products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and resolve the issues you have raised as soon as possible.