LBA300L α-Biological Amylase

Category:

Product Introduction

Physical and chemical properties

| Exterior: | brown liquid | odor: | slight |

| Physical state: | liquid | Flash point (PM closed cup, °C): | NO |

| pH value (25°C): | 5.5~7.0 | Solubility (in water), | 10g/l |

| Specific gravity (g/ml) (at 25 ℃): | ≤1.25 | Vapor pressure (mmHg) | - |

| Evaporation rate (ether=1) | <1 | Vapor density (air=1) | - |

Application example

1.[Application in beer industry]: rice and corn are used as auxiliary materials for beer production. Firstly, the flour is ground through sifting holes of more than 40 mesh.

2.[Application in caramel, glucose and monosodium glutamate ]: Soak rice in water for 1~2 hours in summer and 4 ~ 6 hours in winter, and then make 16-17°Be starch pulp with water rinse and grinding (starch is directly blended, adjust the PH6.2-6.4 and add 0.2% anhydrous calcium chloride (calculated by weight of raw materials). Then add amylase (about 350mL per100 kg of raw materials. stir well and heat to 85 ~ 90.Hold the liquid and liquefy for about 30 minutes. The liquefaction end point is when the dilute iodine solution reacts to reddish brown.

3, [ ln application of the paper making industry] with starch as the slurry of textiles, especially high temperature resistant silk, chemical fiber cotton and wool textiles desizing process, using amylase as the slurry agent is particularly suitable,the enzyme amount is generally .13-0.20%,pH6~7. water bath 40~80.20to40minutes

4,[In application of the paper making industry] LBA3000L is an excellent starch conversion agent, can be used for paper surface sizing starch production, effectively reduce the viscosity of starch, make it suitable for sizing coating, improve the surface strength of paper.For intermittent conversion, can also be used for continuous conversion, suitable for corn starch. cassava starch. the general amount of 60 ~ 300ppm. according to the viscosity used to adjust the amount of amylase.

key word:

Equipment

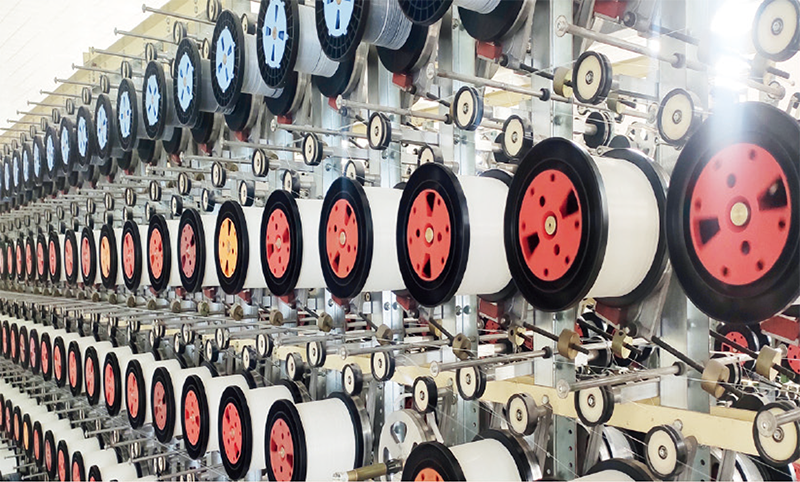

Warping Workshop

All our products are made of imported filament and raw materials, such as the Perlon® Filament. We also use world's most advanced German Schlatter Jagar warping machine. We control product processes and materials from the original procudure, so as to achieve the best product quality.

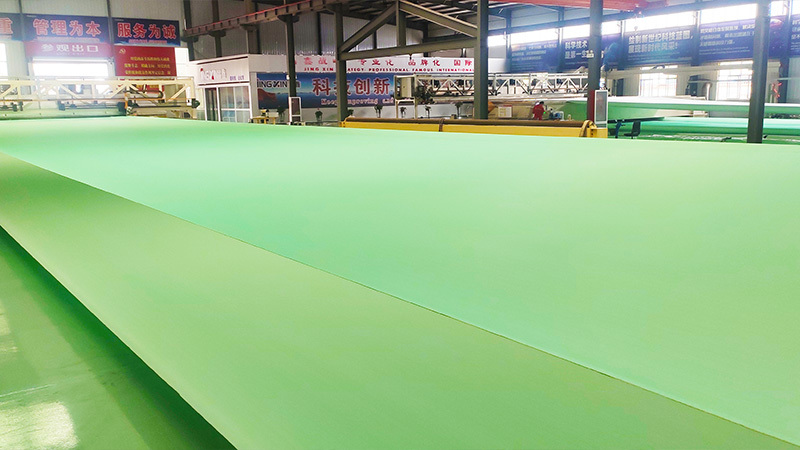

Weaving Workshop

The task of weaving is to interweave the warp and weft processed by the warping process into fabric through the loom according to the fabric specification requirements and certain process design. The warp and weft strength, wear fastness and air permeability of fabrics directly affect the service life of forming fabric and various indexes in production and use processes. We have the most advanced and widest 16 meter Jurgens loom in the world, and the weaving speed, strength and stability have reached the world-class level.

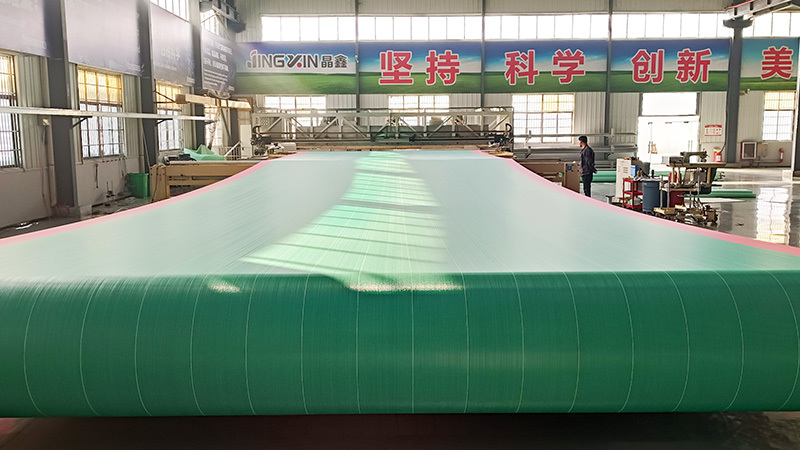

Seaming workshop

The Seaming process is the key process of forming fabrics. In this process, the forming fabrics been size cutting and pre hot setting, then make both ends seamed according to the same fabric design and constructions in the production process. The process requires high technical level, complex process and a long time spending. The firmness and flatness of the seaming will directly affect the requirements in the using process. We have the world's most advanced Austrian WIS automatic seaming machine. The firmness, flatness and stability of the seaming have reached the world-class level.

Seaming Workshop

The Seaming process is the key process of forming fabrics. In this process, the forming fabrics been size cutting and pre hot setting, then make both ends seamed according to the same fabric design and constructions in the production process. The process requires high technical level, complex process and a long time spending. The firmness and flatness of the seaming will directly affect the requirements in the using process. We have the world's most advanced Austrian WIS automatic seaming machine. The firmness, flatness and stability of the seaming have reached the world-class level.

Packaging Workshop

Packaging is an important process. The firmness of the packing box is directly related to the transportation safety and products integrity. We use thickened high-density fumigation-free plywood, supplemented by solid square wood as reinforcing beam. Three thick steel pipes are used for forming fabric packaging, covered with bubble film and wrapped firmly with adhesive tape to ensure that it will not roll and slide during transportation. The bearing capacity of the box is up to 1 ton, which can meet the requirements of ocean transportation.

Honor

High-tech enterprise

Related products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and resolve the issues you have raised as soon as possible.